In modern industrial manufacturing, laser cleaning metal has become one of the most efficient and precise methods for removing rust, oxides, and surface contaminants. Among the pioneers leading this transformation is Mart Laser, a trusted name known for delivering advanced laser systems that redefine how industries approach metal surface treatment.

Unlike traditional cleaning techniques that rely on chemicals or abrasive materials, Mart Laser’s laser cleaning machines use focused laser beams to remove impurities without damaging the base material. This innovative approach ensures safety, sustainability, and accuracy—qualities that make it ideal for industries ranging from automotive and aerospace to shipbuilding and precision engineering.

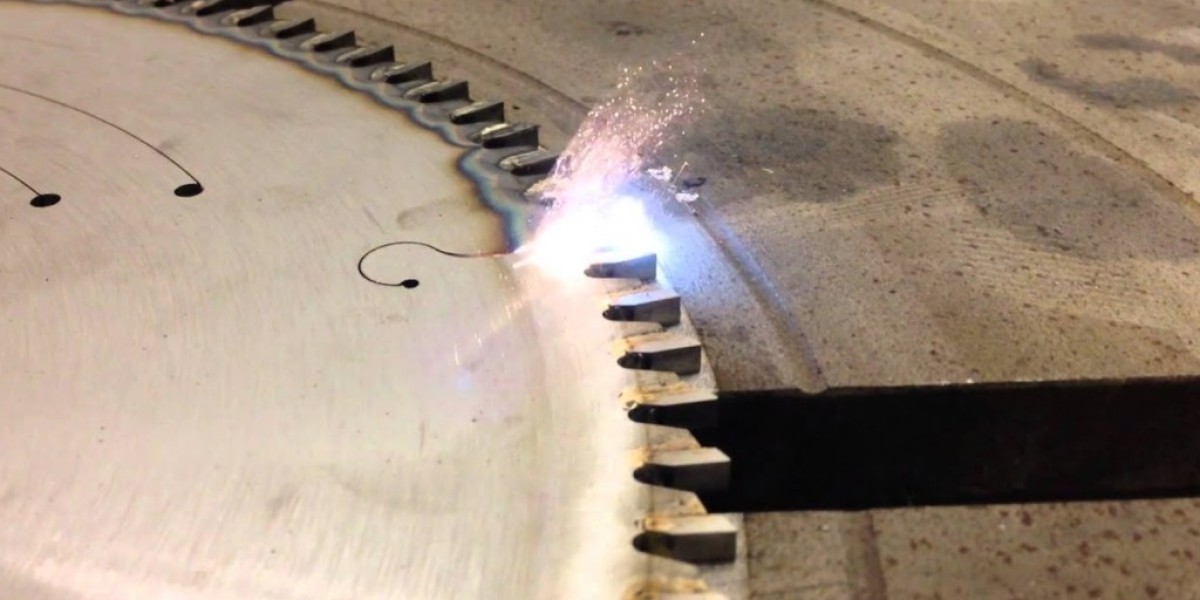

The process of laser cleaning metal involves directing a high-energy laser beam onto the surface of the material. The beam interacts with unwanted layers such as rust, paint, or grease, vaporizing or lifting them away instantly. What makes Mart Laser’s technology exceptional is its ability to control the laser’s intensity and pulse duration, allowing operators to tailor the process for different metals and surface conditions. Whether dealing with stainless steel, aluminum, copper, or carbon steel, Mart Laser machines ensure perfect results every time.

Another advantage of Mart Laser’s equipment is its non-contact and eco-friendly operation. Since it doesn’t use chemicals or generate waste, it provides a clean, efficient solution that aligns with modern environmental standards. This makes it an ideal choice for industries seeking to reduce maintenance costs while improving workplace safety and sustainability.

Ease of use is another highlight of Mart Laser systems. The machines feature user-friendly interfaces and automated functions that simplify operation. Even without extensive training, operators can perform complex cleaning tasks with precision. The compact and portable design of Mart Laser devices further enhances their flexibility, making them suitable for both workshop environments and field applications.

Mart Laser also offers tailored solutions to meet the unique needs of its clients. From small-scale restoration projects to heavy-duty industrial cleaning, each system is designed for long-term durability and consistent performance. The company’s commitment to innovation and customer satisfaction ensures that users get not only a reliable machine but also professional support throughout the product’s lifetime.

In an era where efficiency and precision define success, laser cleaning metal technology by Mart Laser provides industries with the ultimate tool for achieving flawless surfaces. It replaces outdated methods with a fast, clean, and sustainable solution that enhances productivity and product quality.

For manufacturers and restoration experts aiming to upgrade their cleaning process, Mart Laser stands out as the ideal partner. Its dedication to quality, technological advancement, and environmental responsibility continues to shape the future of metal surface treatment worldwide.