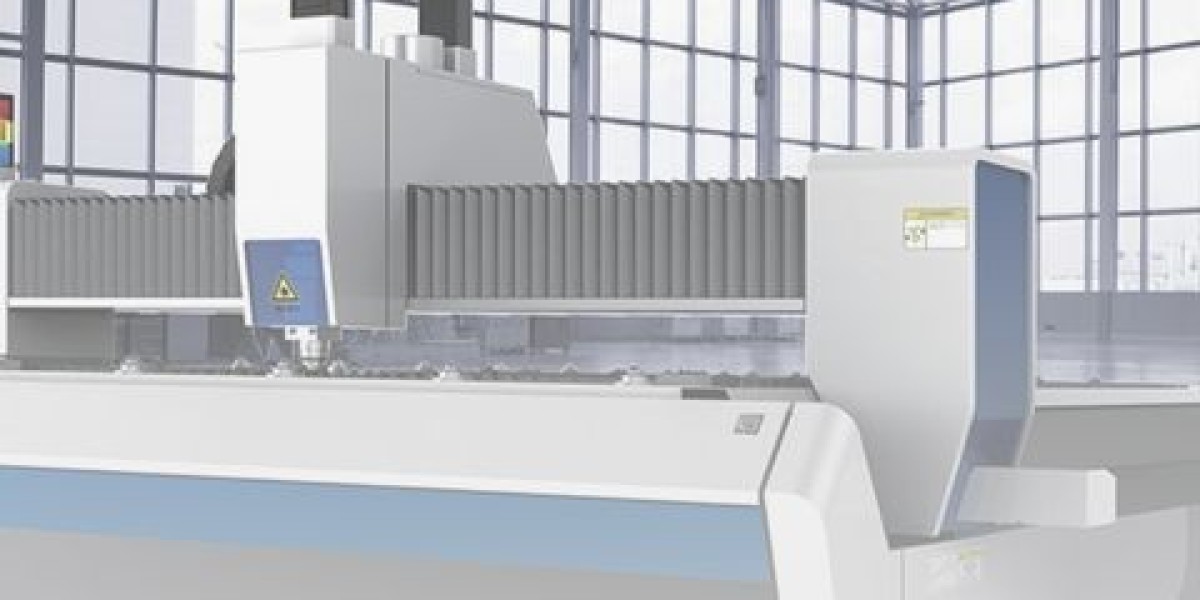

A fiber laser metal cutting machine stands out as one of the most trusted systems for handling a wide range of materials with stability, consistency, and long-term performance. It continues to redefine how workshops, factories, and manufacturing facilities approach metal fabrication, especially when reliability and precision are essential for scaling operations.

A fiber laser metal cutting machine delivers controlled cutting powered by concentrated laser energy, making it suitable for industries where every millimeter matters. Whether a business handles sheet metal production, custom fabrication, or heavy-duty industrial work, this machine supports tasks that demand tight accuracy and uninterrupted workflow.

Why the Fiber Laser Metal Cutting Machine Matters in Industrial Workflows

Industrial facilities often deal with large orders, diverse materials, and strict timelines. For this reason, a fiber laser metal cutting machine is selected by businesses that need to maintain consistent output without sacrificing quality. It provides a cutting environment where every pass is steady, the results are repeatable, and the workflow remains streamlined even during long production cycles.

The design of the fiber laser metal cutting machine allows it to handle various metals such as carbon steel, stainless steel, aluminum, brass, and copper. This flexibility helps manufacturers serve multiple industries without switching equipment or slowing down processes. It is widely adopted in sectors like automotive, construction, aerospace, signage, kitchenware production, interior fabrication, and agricultural machinery.

The Working Approach of a Fiber Laser Metal Cutting Machine

A fiber laser metal cutting machine uses a focused beam transmitted through an optical fiber source, which creates a highly concentrated cutting point. When directed onto a metal surface, the beam generates intense heat to melt the material along a predefined path. The machine follows a programmed design to complete complex cuts, shapes, profiles, and contours with accuracy.

This technology is valued for producing stable cutting lines with clean execution. The machine maintains consistent quality across different sizes of sheets, thickness levels, and batch quantities. Industrial facilities rely on this approach to ensure that every piece meets specifications without unnecessary rework or downtime.

The Role of Automation and Control

The fiber laser metal cutting machine incorporates intelligent control systems that manage the laser source, motion components, cutting head, and path planning. These systems create a predictable environment where operators can monitor progress and adjust settings when needed.

Factories using the fiber laser metal cutting machine often experience better workflow control because the machine supports automated settings for various materials. This reduces manual guesswork and helps teams maintain stable quality even when switching between different job types.

How a Fiber Laser Metal Cutting Machine Supports High Production Capacity

Industrial operations require machines that can stay active for long hours. A fiber laser metal cutting machine keeps production lines running without frequent interruptions. Its cutting process is fast, steady, and capable of handling repeat orders or custom tasks with equal precision.

It is especially useful when businesses receive large-volume sheet metal tasks that must be completed within short deadlines. Manufacturers rely on its ability to deliver uniform cuts, allowing assembly teams to work with metal pieces that align perfectly.

Energy Efficiency and Operational Control

The fiber laser metal cutting machine is known for its efficient use of energy in industrial environments. It converts electrical power into laser output with high efficiency, ensuring that operations remain steady without excessive energy loss during long cutting cycles.

Its controlled mechanism allows users to monitor power levels, adjust cutting speed, and manage the cutting head movements in real time. This supports smooth operations and helps workshops maintain predictable overhead costs.

The Fiber Laser Metal Cutting Machine in Modern Manufacturing Trends

Manufacturing standards have changed, requiring faster delivery, better accuracy, and improved consistency. The fiber laser metal cutting machine aligns with these expectations. Its role in modern fabrication continues to expand because businesses want reliable cutting systems that support growth without compromising quality.

Global industries are shifting towards methods that increase output while maintaining material integrity. A fiber laser metal cutting machine allows manufacturers to create components with minimal waste, accurate dimensions, and reliable finishing. This makes it valuable for companies practicing structured production planning and lean manufacturing.

Why Industries Prefer This Machine for Complex Jobs

A fiber laser metal cutting machine is capable of executing intricate patterns, tight curves, sharp angles, and custom designs without losing alignment. Fabricators use it for advanced tasks that require consistent detail work, such as decorative metal applications, precision engineering parts, machine components, and architectural designs.

Industries dealing with highly detailed or lightweight components benefit from the stability of the fiber laser metal cutting machine. It reduces inaccuracies that typically appear in conventional cutting methods, helping manufacturers deliver premium-quality output.

The Fiber Laser Metal Cutting Machine as a Scalable Investment

Businesses often choose equipment that can support long-term growth. A fiber laser metal cutting machine offers a scalable platform where production volume can increase without the need for frequent equipment changes. As a company expands its services, the same machine can support various metal types, thickness ranges, and product categories.

Its design allows factories to maintain a consistent pace while adding new job types or serving new industries. This scalability makes the fiber laser metal cutting machine a dependable asset for workshops planning future growth.

Operational Stability in Metal Processing

One of the major reasons industries choose a fiber laser metal cutting machine is its stable performance. It continues to deliver predictable results across different work shifts, materials, and operational settings. Fabricators rely on this stability to maintain the reputation of their products and to ensure that each order meets client expectations.

The machine’s structure minimizes vibration, allowing it to maintain accuracy even at higher cutting speeds. This level of stability ensures that workshops can trust the results even during complex or large-scale operations.

Material Handling Consistency

Whether cutting thin sheets for decorative work or thicker plates for industrial parts, a fiber laser metal cutting machine remains consistent in its output quality. Its cutting head and laser beam maintain the precision required to prevent warping, chipping, or poorly defined edges.

This makes it valuable for industries where material integrity must remain intact after cutting, such as structural engineering, equipment manufacturing, and precision components.

The Machine’s Contribution to Workflow Efficiency

A fiber laser metal cutting machine improves workflow by eliminating unnecessary manual processes. It simplifies production planning, enhances order accuracy, and reduces the risk of errors. Operators can load jobs, monitor progress, and manage output with a predictable routine.

This streamlined process allows businesses to manage more orders, reduce delivery times, and maintain customer satisfaction.

Sustainability in Metal Fabrication

Modern industries are focusing on reducing waste and improving efficiency. A fiber laser metal cutting machine supports sustainable metal processing by minimizing material loss and maintaining clean cutting paths. This controlled approach helps factories manage resources responsibly while keeping production costs stable.

Workshops that invest in the fiber laser metal cutting machine often notice better material optimization and improved workflow planning.

Final Thoughts

A fiber laser metal cutting machine plays a crucial role in today’s industrial production landscape. It offers consistent cutting performance, supports large-scale fabrication needs, and delivers accurate results across various materials and designs. Businesses seeking a reliable machine for long-term metal processing continue to choose this solution for its stable cutting mechanism, controlled workflow, and capacity to handle modern manufacturing demands. This machine remains an essential partner for industries that value precision, efficiency, and dependable production quality.