In precision-driven industries, machine stability and positioning accuracy are not optional — they are critical. Yet, many manufacturers struggle with vibration, positioning errors, and premature equipment wear without realizing that the issue often lies in one core component: the cross roller bearing.

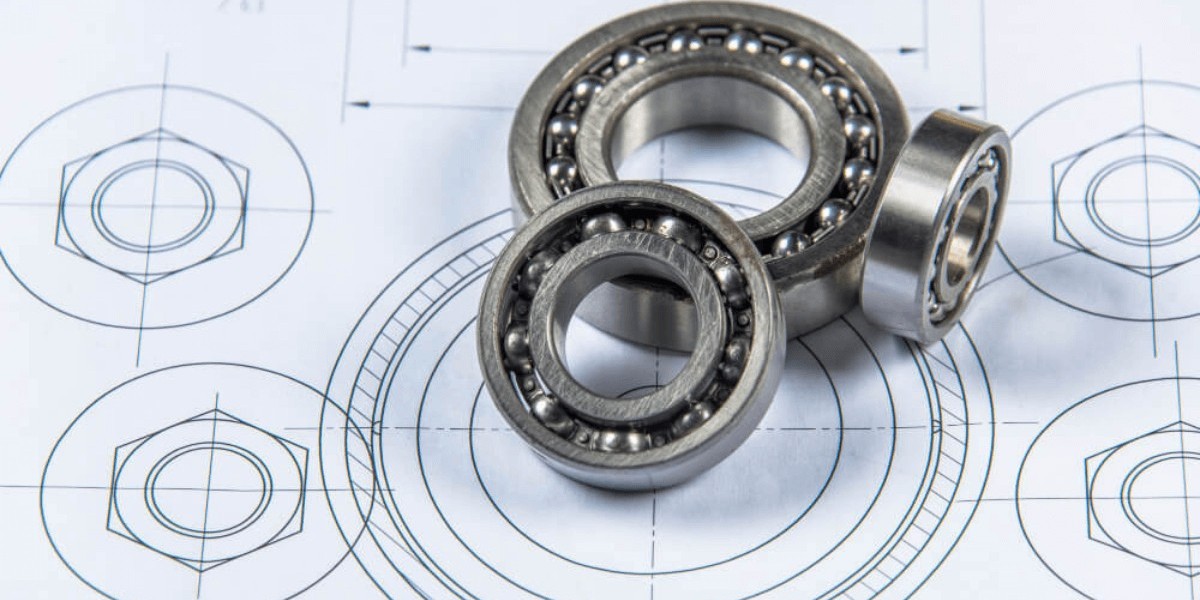

From robotic joints and rotary tables to medical and semiconductor equipment, cross roller bearings play a crucial role in supporting multi-directional loads while maintaining compact design and ultra-high rigidity. If your machines suffer from inconsistent rotation, alignment problems, or unexpected downtime, your bearing choice could be the root cause.

How Poor Bearing Choices Affect Machine Stability

Uneven Load Handling Leads to System Failure

Standard bearings often struggle to support complex combinations of radial, axial, and moment loads simultaneously. As a result, machines experience:

Increased vibration and noise

Structural instability under load

Accelerated wear of internal components

Loss of positioning accuracy

These problems become more severe in applications requiring precise control, such as automation systems, CNC turning tables, and robotic arms. A poorly selected bearing gradually damages connected components, leading to rising maintenance costs and reduced production quality.

Why Cross Roller Bearings Solve These Problems

Multi-Directional Load Support in a Compact Design

A high-quality cross roller bearing uses cylindrical rollers arranged orthogonally. This design allows the bearing to support radial, axial, and moment loads from all directions — all within a compact structure.

This unique load distribution offers several key advantages:

Exceptional rotational precision

Ultra-high rigidity for stable motion

Reduced vibration and deflection

Improved positioning control

These features are especially beneficial for applications like robotic arms, indexing tables, optical systems, and precision measurement equipment.

How Cross Roller Bearings Improve Equipment Accuracy

Enhanced Motion Control and Structural Stiffness

Precision machines rely on accurate and repeatable motion. Cross roller bearings provide high stiffness and minimal elastic deformation, ensuring stable rotational accuracy even under heavy or unbalanced loads.

This makes them ideal for high-precision applications where:

Positioning error must be minimized

Load direction frequently changes

Compact design is essential

Long-term reliability is required

By reducing structural deflection, these bearings help machines achieve smoother motion, cleaner output, and improved production consistency.

Reducing Downtime and Maintenance Costs

Longer Service Life with Lower Failure Rates

Frequent machine failures are not just frustrating — they directly impact profitability. A properly engineered cross roller bearing significantly extends operating life by improving:

Load distribution efficiency

Resistance to wear and fatigue

Thermal stability under high-speed conditions

Lubrication performance

With reduced wear and fewer mechanical failures, businesses benefit from longer maintenance intervals and lower overall operating costs.

Industries That Depend on Cross Roller Bearing Technology

Precision for High-End Applications

Cross roller bearings are widely applied in industries where performance and accuracy matter most, including:

Robotics and automation equipment

Semiconductor manufacturing systems

Medical imaging and diagnostic machines

Industrial rotary tables

Optical and inspection devices

In these sectors, even tiny mechanical errors can result in major financial and production losses. That’s why choosing the right bearing technology is not just a technical decision — it’s a strategic one.

Final Thoughts

If you’re experiencing alignment issues, vibration problems, or inconsistent accuracy in your equipment, it’s time to reconsider your bearing solution. Investing in the right cross roller bearing improves structural stability, increases motion precision, and protects your machinery from long-term damage.

Instead of constantly fighting mechanical problems, make a smarter choice that supports your production efficiency, reduces downtime, and secures long-term reliability.