Noise is a common problem in homes and workplaces. Whether it's the sound of footsteps overhead, traffic, machinery vibration, or simply noisy neighbors, unwanted noise can have a significant impact on comfort, productivity, and health. One of the simplest and most cost-effective solutions is rubber strips, little, flexible bits of Rubber Strips that act to block, damp, or decouple sound paths. Selected and fitted properly, rubber strips can make a big difference in the elimination of noise. This article explores what to look for, the best types, and how to install them for optimal soundproofing.

Why Rubber Strips Help

Before diving into styles and specs, it’s useful to understand why rubber works for soundproofing and noise reduction:

Mass & Density: Rubber has a relatively high mass and density, which helps block airborne sound. The heavier and denser the strip (within reason), the more sound energy it can resist.

Elasticity & Decoupling: Rubber is elastic. Used as a buffer between two materials (e.g. between wall frame and structural wall, or floor board and joist), it decouples the surfaces so vibrations (impact noise, foot traffic, structure-borne sound) are less readily transmitted.

Damping & Absorption: Rubber damps and absorbs vibration and certain frequencies of sound rather than reflecting them, particularly lower frequencies. This reduces resonance, rattling, and reverberation.

Sealing Gaps: Rubber strips installed as seals on doors, windows, and joints seal across air gaps through which sound travels. Tiny gaps let an awful lot of sound escape.

Examples of Top-Performing Rubber Strips & Products

The following are some quality products (from UK suppliers) and how well they perform in various situations. These are not absolute but indicative of what is available.

Isolation Strip P8: Self-stick, rubber-crumb strip 4-8mm thick. Used in stud frames decoupled and joist floor systems. Offers approximately 4-8 dB attenuation of impact transmission.

Regulon Acoustic Isolating Strips (50mm wide): Timber or metal studs can be combined with these strips, utilized beneath partitions for the isolation of noise and vibration at the source. Can tolerate good loads and works fine under low-frequency vibration.

Joist Isolation Strip 50mm: Floating floor structures; over‐90% recycled rubber with self-adhesive backing. Aids decoupling floating floor, both airborne and impact sound reduced.

Acoustic Isolation Strip by JCW: 5mm recycled rubber; used to isolate stud or metal framed wall from building structure; used between floor, wall, ceiling in new build or refurbished buildings.

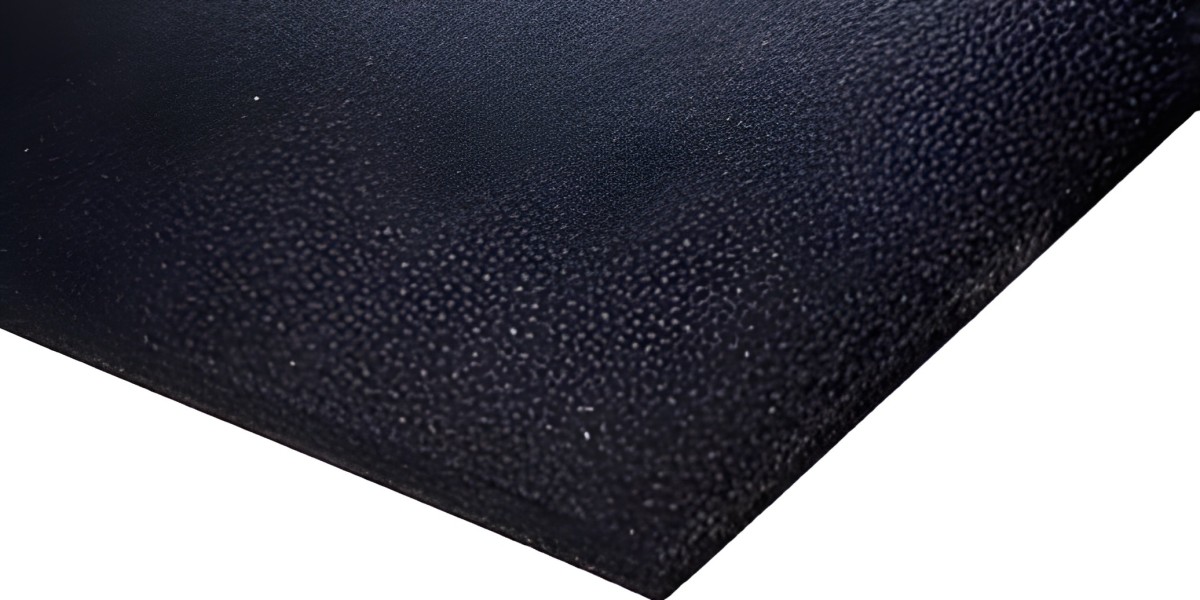

High Density Rubber Soundproofing Sheets / Rolls (by Rubber Co, Slip-Not, Oruba etc.): Additional stronger airborne sound blocking, wall lining, machinery isolation, etc. These are typically able to reduce sound by many dBs depending on thickness: e.g. 3mm to 6mm sheets offering moderate reduction, thicker ones up to 20-25mm for more heavy duty.

How to Choose the Right Rubber Strip for Your Situation

To select the best Rubber Protection Strip for your noise problem, use the following decision process:

Decide what kind of noise

Airborne noise (speech, traffic, music coming through walls) → needs mass, sealing, continuous barriers.

Impact or structure-borne noise (footfall, vibration, machine vibration) → needs decoupling (rubber isolating layers) + damping.

Identify where the sound is coming in / traveling

Through walls, ceiling, floor, doors, windows, frame joints, or equipment mountings.

Any un-buffered structural interface will leak noise.

Select installation constraints

Space: how thick can your solution be before it will take up too much space?

Whether you will be able to get access to both sides (e.g. for floors or walls).

Select the correct strip or sheet

For small gaps / door perimeters / windows: thin high-density strips, self-adhesive.

For floating floor or stud frames: isolation strips with adequate compression and width to decouple.

For vibration or heavy machinery: wide, thick anti-vibration strips / mats.

Supplement: with other soundproofing options

Sealing all: gaps (skirting, cracks, joints, around frames) with acoustic sealant.

Adding mass: (rubber sheets, additional plasterboard) or absorption (acoustic panels, insulation) if required.

Decoupling structural elements where possible (floating floors, resilient channels).

Installation Tips & Best Practice

Any amount of good rubber strip will be useless if badly fitted. Some hints for achieving maximum performance:

Constant contact: Where the strip is to act as a seal or isolation, ensure there are no gaps under and around the strip. Gaps will reduce effectiveness greatly.

Correct compression: With under-floor and joist strips, the strip needs to be compressed slightly under load but not flattened out ("bottomed out"). Choose thickness and density as required.

Seal edges well: After strips are installed, seal edges of walls, joints, or where panels/boards meet to avoid sound leaks. Acoustic sealant or mastic is recommended.

Make strip width and shape fit the application: Fit wide strips over wide studs or joists; fit narrow strips over frames or where sealing must be done. The strip must fit the contact area to decouple effectively.

Consider environment conditions: In damp or external areas, ensure the rubber is oil-resistant, heat-resistant, UV-resistant, moisture-resistant, etc. Some strips will deteriorate if installed in extreme conditions.

Layering: On most occasions, combining rubber strips with other soundproofing solutions (e.g. sheets, insulation, double layer plasterboard) performs much better than using strips on their own.

Examples & Performance

A Joist Isolation Strip (50mm wide) within floating floors will reduce structure-borne / impact sound by ~3-5.

Isolation Strip P8 (4-8 mm thickness) on stud or joist systems also offers a slight but noticeable reduction in impact/transmitted noise.

Rubber sheet matting (such as 6-10 mm or more) applied to a wall can significantly reduce airborne sound like voices or traffic, particularly when complemented with good sealing and additional layers.

Recommended Rubber Strip Products

The following are some particular product recommendations that commonly earn good customer reviews or technical scores. They are not all "strips" in the strict sense, but they indicate what rubber-based acoustic products are capable of.

Regulon Acoustic Isolating Strips (50mm) – good quality stud frame or partition application to reduce structure borne sound.

Isolation Strip P8 – very good for decoupling in flooring / stud wall.

Joist Isolation Strip 50mm – very good recycled rubber strip, self-adhesive, very good in floating floor assemblies.

High-density rubber soundproof sheets / mats for walls or floors if additional mass is required. Thick sheets or rolls are convenient.

Anti-vibration strips / mounting strips for machinery (e.g. Vibe Guard types) to assist with reducing vibration noise.

Conclusion

Rubber strips are among the most effective and affordable "first steps" to deal with noise problems. While not typically enough to completely soundproof all cases (especially low-frequency sound), they're perfect for sealing, decoupling, and reducing impact and airborne transfer. With the right rubber strip choice and correct installation, sealing, and where needed additional soundproofing treatment, you'll notice the difference your area is quieter and more relaxed.

If you prefer, I can compile an individualized product comparison table for your region (UK or otherwise) with prices, decibel reductions, pros & cons to help guide your choice. Would you like me to do that?