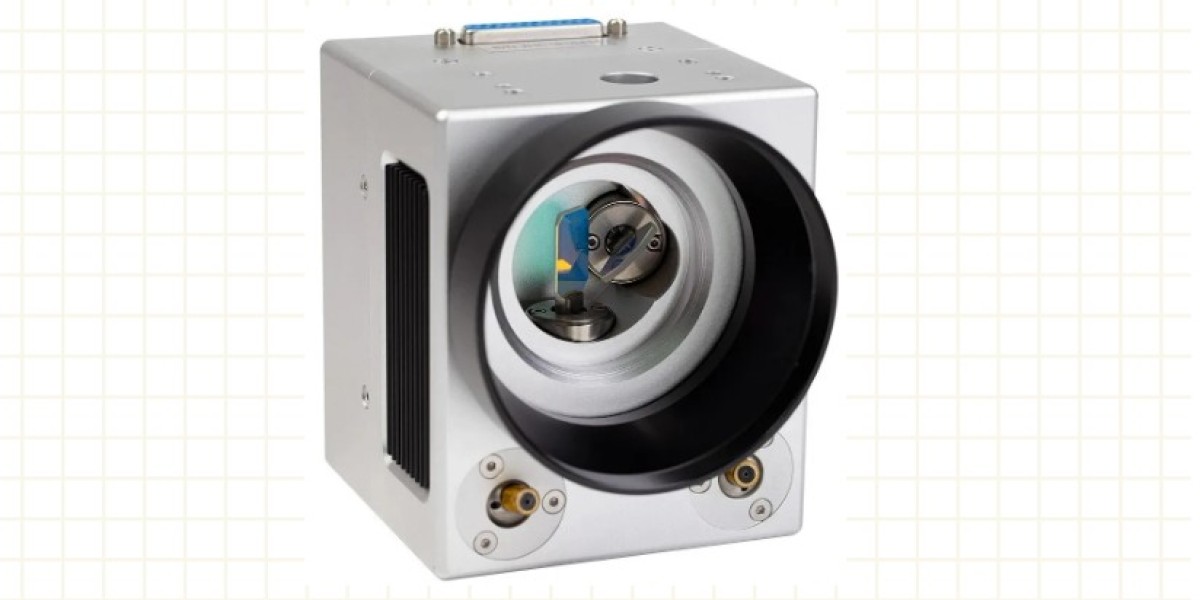

As industries move toward smarter and more automated production, laser processing technologies are becoming essential for achieving stable, high-quality results. Among these innovations, the scan head, galvo laser, and 3d laser galvo systems have become the most widely adopted solutions in precision marking and engraving.

1. The Role of the Scan Head in Precision Manufacturing

A high-performance scan head controls the direction of the laser beam by adjusting internal mirrors at high speed. This allows manufacturers to achieve:

ultra-fast marking

sharp and clean beam positioning

stable output on various materials

Whether producing consumer electronics or metal components, the scan head determines the final quality of the marking process.

2. Why Galvo Laser Systems Are the Industry Standard

A galvo laser system stands out because it operates without any mechanical movement of the working surface. Instead, galvanometer mirrors steer the laser beam swiftly and precisely. This provides major advantages:

significantly higher processing speeds

improved accuracy over long production cycles

consistent marking even during high-volume output

reduced downtime and lower maintenance

For factories seeking efficiency without sacrificing quality, the galvo laser is one of the most reliable technologies available.

3. The Advantage of 3D Laser Galvo Technology

Traditional 2D laser systems struggle with curved, angled, or multi-layered surfaces. A 3d laser galvo system solves this by dynamically adjusting both the focal height and the scanning path. This enables precise marking on:

curved metal housings

automotive plastic parts

molded packaging

uneven industrial components

The flexibility of 3d laser galvo technology makes it a preferred choice for manufacturers producing complex or non-flat products.

4. Key Industries Using These Technologies

The combination of scan head, galvo laser, and 3d laser galvo solutions is already widely used in:

automotive manufacturing

electronic component coding

medical equipment engraving

aerospace parts identification

industrial automation lines

These industries benefit from improved consistency, faster cycle times, and higher productivity.

5. Choosing the Best Laser System for Your Applications

When deciding between a standard galvo laser or a more advanced 3d laser galvo system, businesses should consider:

product surface complexity

required marking depth and speed

available production space

integration with existing automation equipment

software compatibility and future upgrade needs

Selecting a system with the right scan head configuration ensures long-term stability and reliable performance.

Conclusion

With rapid advancements in industrial production, the scan head, galvo laser, and 3d laser galvo systems have become powerful tools for achieving high-speed, high-precision, and highly flexible laser processing. Companies adopting these technologies gain a strong competitive edge through better efficiency and superior marking quality.