As electronic devices become smaller, faster, and more reliable, manufacturers are under increasing pressure to deliver components with tighter tolerance levels and consistent performance. One essential tool enabling this high level of precision is the resistor trimming machine, a system designed to fine-tune resistor values with remarkable accuracy. This technology has quietly become a cornerstone of modern electronics production.

1. What Is a Resistor Trimming Machine?

A resistor trimming machine is an automated system that adjusts the resistance value of thick-film or thin-film resistors through laser trimming. Instead of manually selecting or discarding components that fail tolerance requirements, manufacturers can use a trimming machine to precisely laser-cut the resistor material, achieving the exact ohmic value needed.

This increases production yield, reduces waste, and ensures stable performance in circuits that require high accuracy.

2. How Laser Trimming Technology Works

Most resistor trimming machines use a high-precision laser beam to remove microscopic amounts of material from the resistor surface. The machine monitors resistance in real time and adjusts the laser output until the component reaches the target value.

Key advantages include:

High trimming accuracy (down to ±0.1% or better)

Non-contact processing, which avoids mechanical stress

Fast cycle time, ideal for mass production

Stable performance, even for miniaturized components

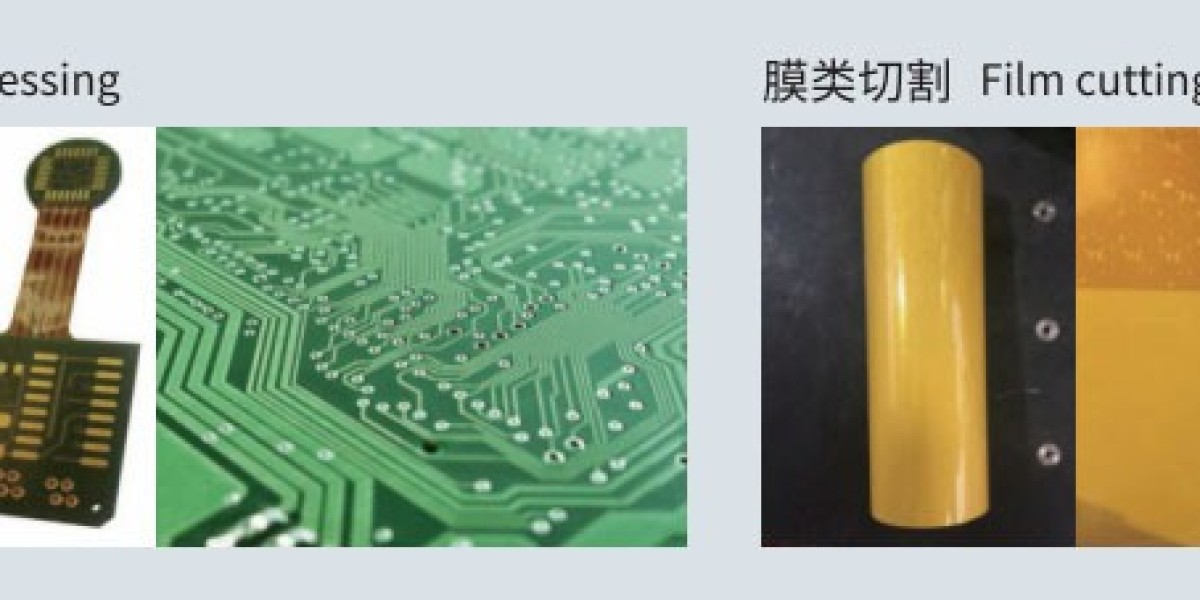

This makes the technology suitable for complex modern electronics such as automotive control units, communication devices, sensors, and medical equipment.

3. Why Manufacturers Rely on Automated Trimming

With the rapid growth of smart devices and high-performance components, traditional manual adjustment is no longer feasible. A modern resistor trimming machine offers:

Fully automated trimming workflows

Consistent, repeatable quality

Real-time measurement and correction

Improved product reliability

By integrating trimming machines into production lines, companies can meet strict international standards and ensure component stability even under demanding working conditions.

4. Applications Across High-Tech Industries

Resistor trimming machines play an essential role in industries requiring ultra-precise circuit performance, including:

automotive electronics

aerospace and defense systems

IoT devices and smart home equipment

industrial sensors and instrumentation

medical electronic equipment

Any product that depends on stable and predictable electrical behavior benefits from precision trimming.

5. Choosing the Right Trimming Machine System

When selecting a resistor trimming machine, manufacturers typically consider:

trimming accuracy and stability

supported resistor materials (thick-film, thin-film, metal-glaze)

laser source type and beam quality

automation level and software capability

integration with testing equipment

long-term reliability and maintenance cost

A well-chosen machine not only improves yield but also strengthens the overall competitiveness of the production line.

Conclusion

As electronic components continue to evolve toward higher precision and miniaturization, the resistor trimming machine has become an essential tool for ensuring consistent quality and accurate resistance values. Its combination of laser-based precision, automation, and high efficiency makes it a powerful asset for manufacturers aiming to meet the growing demands of modern